Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

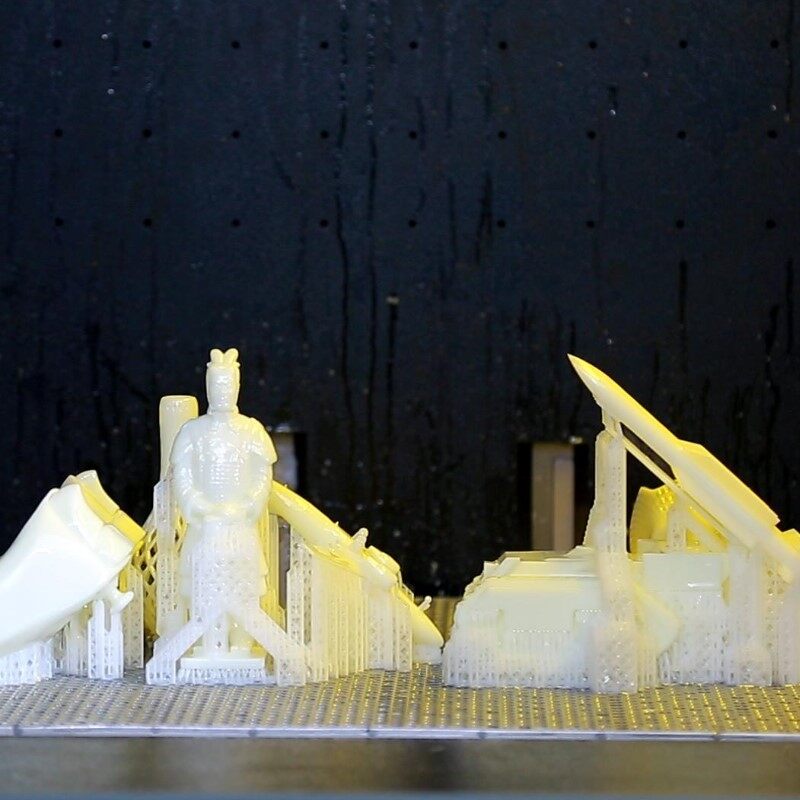

SLA 3D Printing

Our SLA 3D Printing technology utilizes a high-resolution laser to solidify liquid resin layer by layer, resulting in stunningly accurate and intricate models. From intricate jewelry pieces to architectural prototypes, SLA 3D Printing ensures every intricate detail is faithfully reproduced, capturing the essence of your vision.

Stereolithography or SLA is a resin-based 3D printing technology that produces highly accurate, high resolutions parts with an excellent smooth finish. The combination of high speed, low-cost per part and well-established materials makes stereolithography an ideal choice for prototypes and low volume production.

Specification

|

Our Capabilities |

Industrial SLA |

|

Maximum Build Size |

800 x 800 x 550 mm (31.5″ x 31.5″ x 21.6″) |

|

Lead Time |

2-3 days |

|

Resolution |

± 0.2mm |

|

Prototyping Applications |

High aesthetic and accurate to CAD prototypes |

|

End-Use Applications |

Low-volume, fine detailed parts |

SLA Materials

|

|

Photo |

Description |

Material Reference |

Appearance |

|

High Temp Resin

|

|

We offer high-temp resin options. They are designed to be used in high-temperature scenarios such as ducting, molding, and for prototyping applications in the automotive and aerospace industries |

YG H-3001, Lasty-702, GH100 |

Grey, Yellow, Red Translucent |

|

Rigid Resin |

|

Rigid SLA resins offer a high level of stiffness and an exceptionally smooth finish. Due to its strength and resistance to deformation over time, it can be applied in some functional applications such as creating jigs and fixtures. |

SOMOS 8000, TOP31B |

White Transparent, Black |

|

Nylon-Like Resin |

|

Taurus is a nylon-like SLA material that offers the look and feel of an injection moulded part. It has strong mechanical properties and is ideal for outdoor applications, casings and some functional prototypes. |

Taurus |

Blue-gray (depending on finish) |

|

Transparent Resin |

|

We can 3D print high aesthetic transparent parts. Transparent SLA resins are generally stiff. Because of the structure required to support your model during printing, freedom of design is limited. |

Crysta-8QEF1, Godart 8001 |

Transparent |

|

Generic Resin |

|

C-UV 9400 is an ABS-like SLA resin which has accurate and durable features. It can be applied in master patterns, concept models, general parts and prototypes in the field of automotive, medical and consumer electronics industries. |

C-UV 9400 |

White |

|

High Toughness Resin |

|

As the name suggests, high toughness resins are hard to break. Such SLA resins are extremely stiff, resistant to cyclic loads, and very strong, designed to withstand high stress or strain for short periods of time. High toughness SL resins can be applied in some functional applications. |

Godart 8228, Lasty-R, SOMOS Taurus |

Light Green, Yellow, Black |

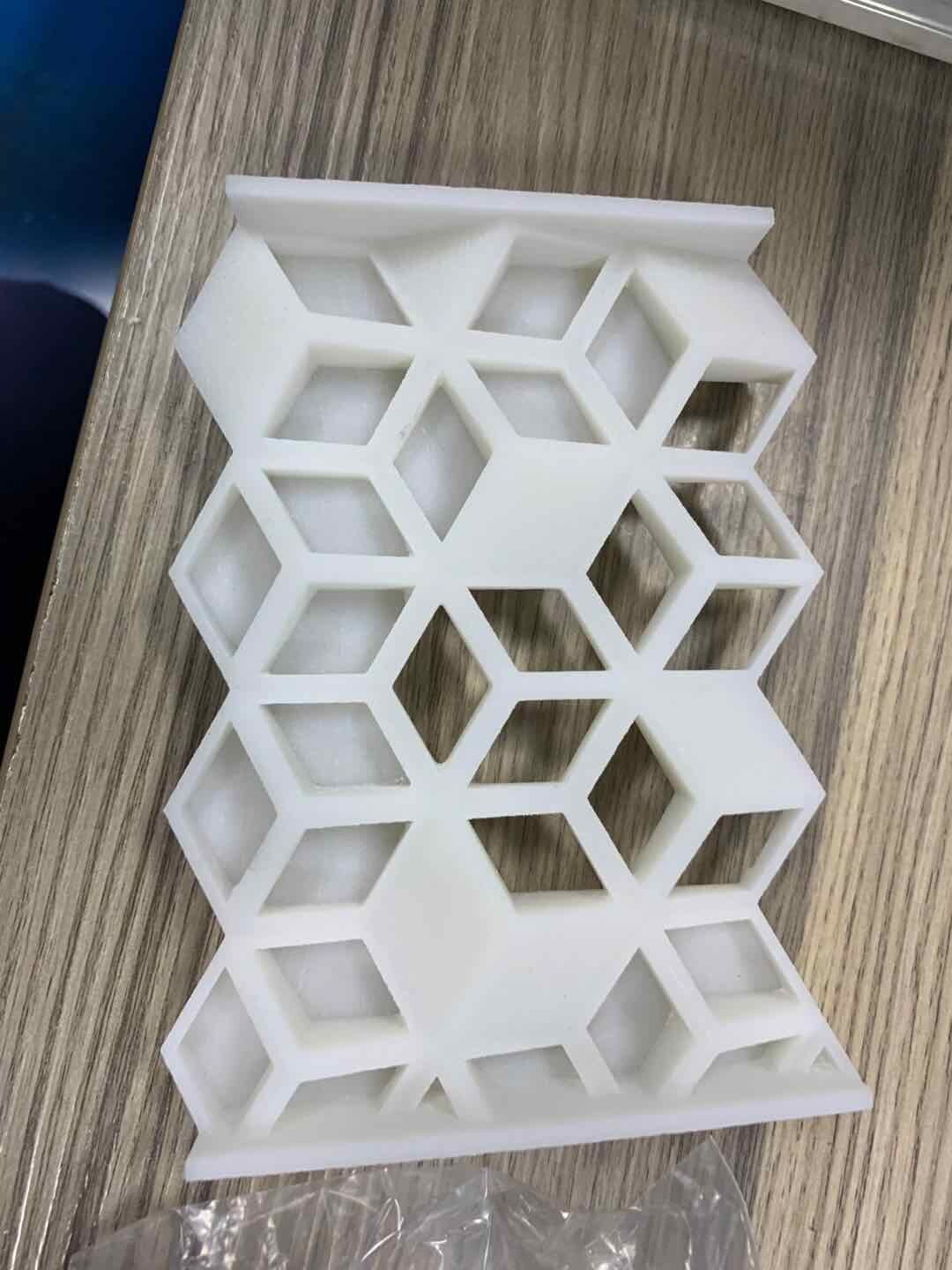

Typical SLA Finishing Options

|

|

Applicable Materials |

Color |

Description |

|

Sanding |

All |

/ |

Sanding SLA printed parts is often the best way of smoothing edges, removing blemishes, and getting rid of any leftover support marks. |

|

Spray Paiting |

All |

Black, Pantone/ RAL colours |

Spray painting is a quick way to colour parts. It can also reach areas that cannot be reached with a brush. |

|

Plating |

ABS |

Metallic |

Plating is method of adding a thin layer of metal of the outer layer of a material. It is used to harden, decorate and improve wearability of parts. |

About The Process

SLA 3D printing builds parts one layer at a time using a highly accurate UV laser to solidify one layer of photosensitive resin, which makes the parts accurate and in good surface. The parts need to be built with support structures which are removed during post process.

Advantages of SLA 3D Printing

Wide Range of Materials:stereolithography offers a vast material selection with a range of properties.

Finest Detailing:SLA is one of the best 3D printing technologies for creating very accurate and finely detailed parts.

Rapid Turnaround:Because SLA can create complex and multi-material parts in a single operation, significantly less build time is needed vs. traditional manufacturing.

Smooth Finish:SLA creates parts with an excellent finish which remarkably resembles end use items like injection moulded parts.

Disadvantages of SLA 3D Printing

Generally Brittle:SLA parts are generally brittle and not suitable for many functional applications.

Degradation Over Time:Due to the photosensitive nature of SLA resins, SLA parts will experience degradation over time when exposed to sunlight.

Requires Support Structures:SLA prints always require support structures, which must be removed in the post-processing stage.

The Application of SLA 3D Printing

The many advantages of SLA 3D printing have made it a choice for many applications across different industrial sectors for many years, including:

- automotive

- consumer goods

- gaming

- robotics

- medical

- jewellery